Are you tired of making continuous purchase receipts manually?

For businesses, dealing with large volumes of purchase orders, management of these documents is of vital importance since irregularity and absence of accurateness in the PO management may create a chaotic environment.

The Procurement process of Materials will be completed when Purchase receipt is received by the buyer after inspection. Roadmap handles the procurement process in simple following steps. Multiple GRNs can be created for the different Purchase order as a batch process correspondingly for the Suppliers.

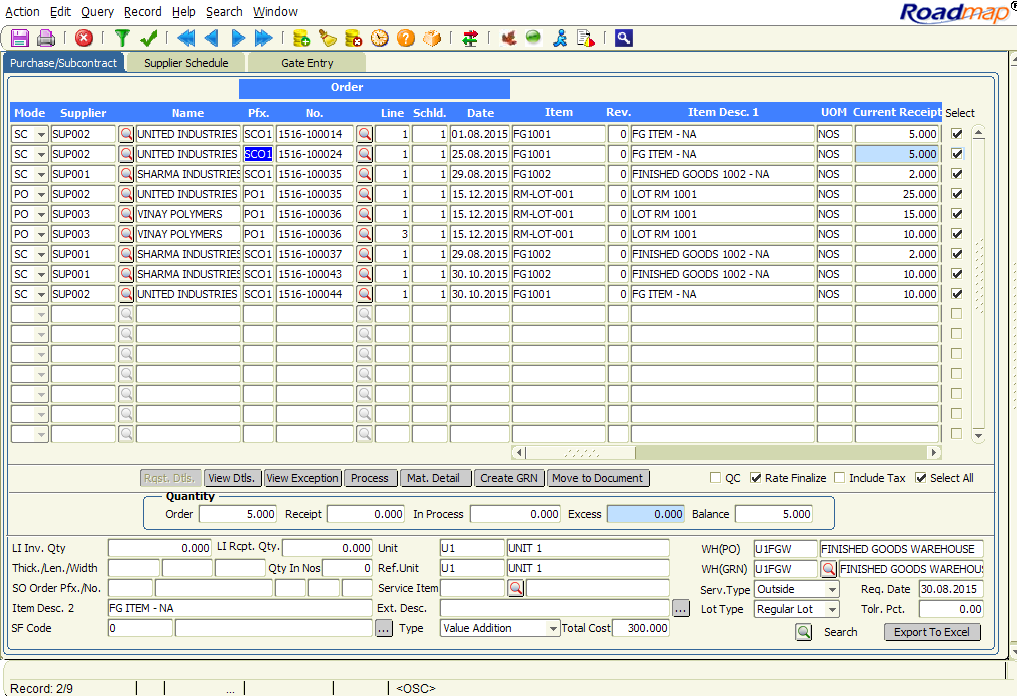

Let us see how Purchase Orders are converted into GRN. The following screen allows the users to create multiple GRN corresponding to the supplier to whom the Purchase Orders are created.

(a) Order Quantity – Displays the actual Purchase Order Quantity

(b) Receipt Quantity – Displays the received quantity of the PO

(c) In Process – PO quantity pending to be received

(d) Excess Quantity – Quantity supplied by the supplier in Excess after Tolerance

(e) Balance – Remaining Qty of PO yet to be converted to GRN.

The above consolidated view of PO status provides you a sharply defined PO status quite instantly while creating GRN itself rather than navigating to multiple screens.

Also we provide the schedule information for Purchase Orders such as Ordered Date, Required Date and other relevant information including Tolerance%, Discount % and Tax details in a Separate dialog, Physical attributes of the materials purchased such as Thickness / Length / Width.

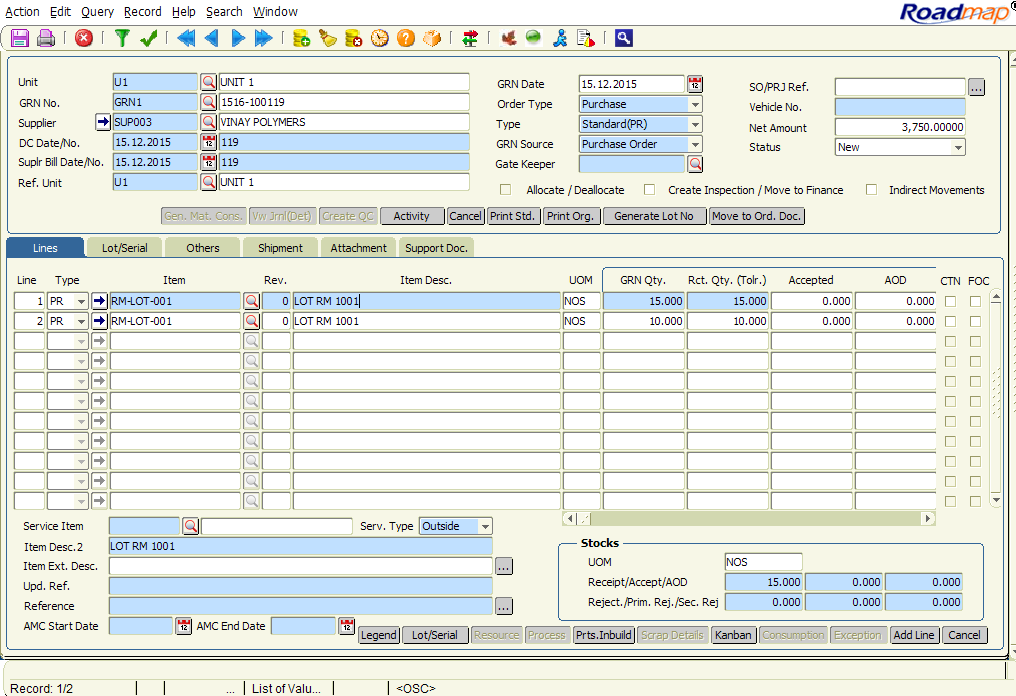

GRN created from the above purchase order screen carries all the data described above with it for easy reference and the same can be inferred from the below figure.

The figure you see here is the GRN (Goods Receipt Note) of purchase receipt screen.

Inspection processes in GRN and how the rejection materials are handled will be discussed under next blog.